Foxboro 43AP Pneumatic Controller

Inhouse product

-

Brushcutter FS 250 Stihl brand

₦320,000.00 -

TES-1350A Sound Level Meter (A & C Frequency)

₦379,901.00

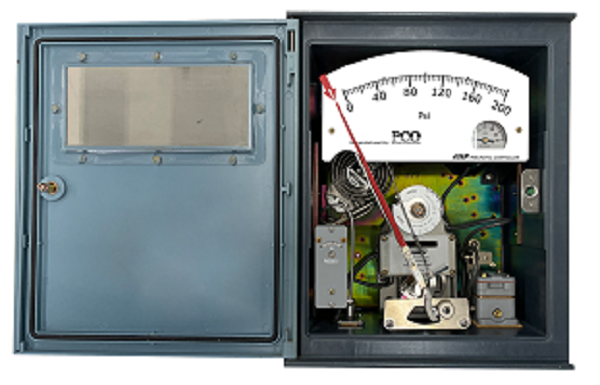

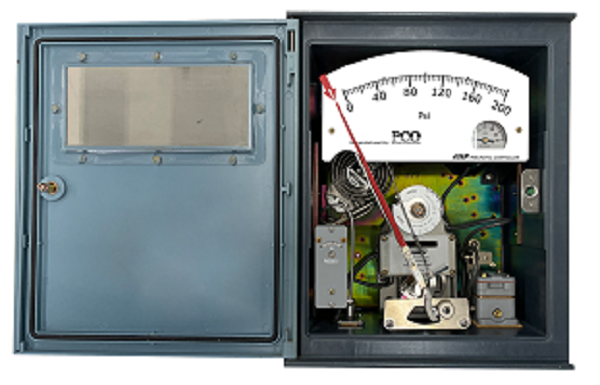

Foxboro 43AP Pneumatic Controller

The Foxboro 43AP pneumatic controller is a versatile process instrument controller that can be used to control pressure, temperature, flow and level.

As with all process controllers, the Foxboro 43AP pneumatic controller continuously detects the difference between a process measurement and its set point.

Model 43AP Controller continuously detects the difference between a process measurement and its set point, and produces an output air signal that is a function of this difference and the type of control.

The output signal is transmitted to a control valve or other control device. The process measurement, set point, and output signal are indicated on the controller

43AP Pneumatic Indicating Controllers are built to withstand the elements, featuring a glass fiber reinforced case and a gasketed door with a shatter-resistant polycarbonate window. Their flexibility of use makes these instruments applicable to essentially any process. This is indicative of Invensys Foxboro®; it leads the industry with the most extensive selection of element constructions and ranges available.

Designed to specify and control temperature, pressure, vacuum and differential pressure, the notably reliable 43AP Series exhibits a wide range of derivative and integral (reset) adjustments: the derivative unit, from 0.05 to 50 minutes, and the integral unit with the full range, from 0.01 to 50 minutes.

Multiple options for control modes are offered for these devices, including the following:

- On-off

- Proportional

- Proportional plus derivative

- Proportional plus integral (reset)

- Proportional plus integral plus derivative

- Differential gap

- Automatic shutdown

43AP Pneumatic Indicating Controllers’ construction meets IEC IP53 standards and offers the environmental protection of NEMA® Type 3. In the event of a power failure, and, consequently, the highly probable loss of supply pressure, process-driven indication is not affected.

Demonstrating mounting versatility, 43AP Pneumatic Indicating Controllers may be mounted in a panel, on a flat surface, on a continuous vertical pipe, or on a vertical pipe stub. To shield the control unit and measurement element from the effects of case stresses caused by mounting, and thus, maintain precision during use, both components are mounted on a firm steel plate.

These devices support a long list of optional features, such as the following:

- Remote pneumatic set point

- Type 70 electric contacts

- Control valve mounting

- “Batch” function

- Internal bumpless automatic-manual transfer stations (two types) – For this selection, a basic 2-step procedure provides for bumpless-balanceable transfer between automatic and manual control. To get to the transfer station, the door must be opened, thus preventing unintentional transfer.

Principle of Operation

1. A differential linkage measures difference between measurement pointer and setting

index positions. This error signal moves proportioning lever.

2. Proportioning lever pivots at its center on end of a flat spring.

3. This motion changes flapper nozzle relationship, causing relay to establish an output

pressure.

4. Output pressure is fed back to proportioning bellows, which acts through

proportioning lever to rebalance flapper nozzle.

5. Reset bellows and tank assembly are used when measurement must be maintained

exactly at control point (without “offset”).

6. Derivative tank assembly is used to improve system response to a slow process.

PUT TO POINTER

Specifications: